There’s always a lot of speculation and comment about the British manufacturing industry and whether it’s on an upward or downwards trajectory, but for Chas Shale of GTK UK, there are still plenty of reasons to be cheerful about the demands for UK manufactured products in the electronics industry. Chas is the Manufacturing Director at GTK and so has plenty of direct experience of UK manufacturing, demand and supply.

There’s always a lot of speculation and comment about the British manufacturing industry and whether it’s on an upward or downwards trajectory, but for Chas Shale of GTK UK, there are still plenty of reasons to be cheerful about the demands for UK manufactured products in the electronics industry. Chas is the Manufacturing Director at GTK and so has plenty of direct experience of UK manufacturing, demand and supply.

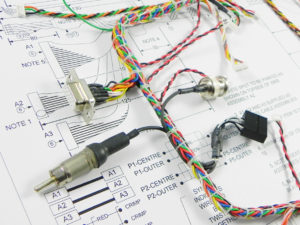

.In high security industries, such as aerospace and military, the decision to use UK manufactured product is often for security and confidentiality reasons. In other industries, it can meet customers’ logistical requirements to purchase a product from the UK as the supply lead time is shortened in comparison with products manufactured offshore.

“At the end of the day, it’s all about the customer,” said Chas. “From GTK’s perspective we can offer product manufactured in the UK, Romania or the Far East. We can also offer customers a variety of different build models combining the benefits of different manufacturing locations. When we receive new enquiries from customers, we will work out the most cost-effective option for the customer. But for each enquiry there may be a range of factors that need to be considered, including approvals required, end delivery location, lead time parameters, AML and so on. In some cases there may be an overriding factor that will determine the products’ manufacturing location.”

GTK’s UK manufacturing facility has multiple approvals including ISO 9001:2015, ISO 14001:2015, UL Wire Harness Traceability Programme and AS9100D accreditation. It also offers a FastTrack prototyping service whereby product can be delivered within five days of enquiry.

“We have a global manufacturing footprint at GTK,” said Chas, “but our UK facility is central to our business model. Our AS9100 approval governs all aspects of our operation, and all products manufactured in our UK facility benefit from the approval’s stringent requirements for quality, regardless of their intended application. We can also use UK manufacturing as an option for new product designs, where starting volumes are low and potentially unpredictable, and then move manufacturing to a more suitable location when volumes ramp up. We are seeing an increasing flow of new business through our UK facility with no sign of any slowing down.”